What Is the Highest Power Diode Laser

You may be wondering how much it costs to buy a used or new laser cutter for your business. What is the average cost of a laser cutter in your region? The most affordable budget laser cutters cost between $2,600 and $300,000. This includes shipping, taxes, customs clearance, support, and service. Prices vary depending on brand and type. You may also want additional features such as customized design, custom size, laser generator, power, rotary attachments, controller, parts, upgrades, setup, troubleshooting, or other features. Below is a list of the average costs.

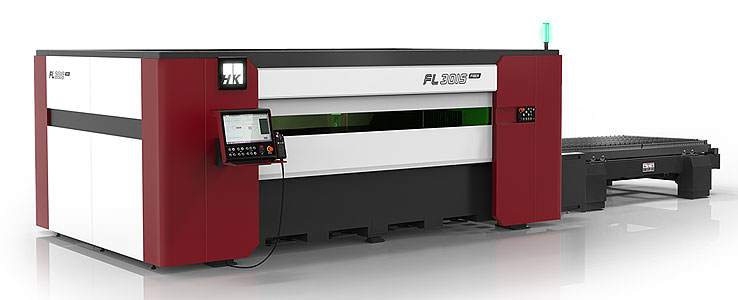

You should pay special attention to the core parts of your machine, including laser generator, cutting head and servomotor, guide rail, water cooler, and others. These parts will impact the machine's accuracy and cutting speed.